Water-to-Air Heat Exchanger – All you Need To Know

No scientist has ever been able to create a fluid that transmits heat more effectively than simply plain old water, which is one of nature's most amazing discoveries!

As its name sounds, a water-to-air heat exchanger transfers heat from water to air. Many people think these look like a radiator for a car. The hot water passes through small copper tubes that have metal fins attached. The circulating hot water from the boiler heats the tubes and fins. When warmth is needed, a blower fan turns on and blows air through the fins and tubes and voila – warm air!

Design of Water to Air Heat Exchangers

Water to air heat exchangers consist of a tube bundle that contains water, which is used as the heat transfer fluid, and a series of fins that are attached to the tubes. The fins increase the surface area of the tubes, allowing for more efficient heat transfer between the water and air. The air flows over the fins, absorbing heat from the water in the tubes, and then is distributed throughout the building.

Water-to-air heat exchangers are most commonly used in forced air ducts. See drawing below. These heat exchangers are often installed in the forced air furnace plenum which is located above the furnace. These come in several sizes, and are often installed by simply attaching “L-Brackets” to the inside of the plenum that the heat exchanger lays on in a “flat” orientation.

Outdoor wood boiler water-to-air heat exchangers come in different sizes, some as small as 12”x12” for a small room up to 24”x24” and larger for bigger spaces to be heated.

Specifications:

- All exchangers are 3 1/2" thick.

- Aluminum fins are installed at 12 fines per inch.

- All exchangers are triple pass design.

- Tubing is 1/4" copper.

- Our exchangers have 1" copper outlets and can be installed with either sweat fittings or push fit type fittings.

- Exchangers will work with chilled water also.

- We stock many sizes, always order the largest size that will fit into your plenum.

Applications of Water to Air Heat Exchangers

Water to air heat exchangers are used in a wide range of applications, including:

- Heating and cooling of buildings

- Heat recovery ventilation systems

- Industrial process heating and cooling

- Refrigeration systems

- Solar thermal systems

THESE HEAT EXCHANGERS ARE TO BE HOOKED UP TO AN OUTDOOR BOILER OR A CHILLED WATER SOURCE.

These heat exchangers can also be used as a stand alone heat source by simply attaching a fan or squirrel cage to one side of the unit. They can be installed in either the hot air side or the cold air return of a furnace. Please note that if installed in the cold air return you will need to install a 3 way zone valve in order for the fan to operate properly.

This heat exchanger is of a new style which does not require bending of your duct work.

This new style heat exchanger can be easily installed by just slipping it into the plenum and attaching with self threading screws. You will not need any special tools to install. This unit is easier to install than others on the market because it attaches from the front instead of the side.

Water to Air heat exchangers, often called duct coils or furnace radiators, are used for installing into forced air furnace to provide heat from hot water. They are usually installed into the cold air side of the furnace if that is the best option. They work in much the same way as the central air conditioning unit.

The following things should be taken into consideration when installing a duct coil.

(1) Size the coil so that the fins take up the maximum amount of the plenum as possible.

(2) Securely fasten the unit so that it doesn't rattle.

(3) Make sure there are no foreign objects are touching the fins or the tubes.

(4) Duct tape any air leaks.

(5) Do not bend the fins. If you do, straighten them as best you can. A tool called a "Rake" is available for straightening the fins.

(6) If you are going to run your outside heat in the summer install a bypass valve.

(7) A duct coil installation kit makes installing the heat exchanger easier.

Advantages of Water to Air Heat Exchangers

Water to air heat exchangers offer several advantages, including:

- Energy efficient: Water to air heat exchangers are highly efficient at transferring heat, which can lead to significant energy savings.

- Cost effective: Water to air heat exchangers are typically less expensive than other types of heat exchangers, such as air to air heat exchangers or plate and frame heat exchangers.

- Space saving: Water to air heat exchangers are compact and can be easily integrated into HVAC systems, which can help to save space in buildings.

- Low maintenance: Water to air heat exchangers are easy to maintain and require minimal upkeep.

Limitations of Water to Air Heat Exchangers

Water to air heat exchangers also have some limitations, including:

- Limited temperature range: Water to air heat exchangers are typically designed for temperature differentials of less than 20°C, which limits their use in high temperature applications.

- Corrosion: Water to air heat exchangers can be susceptible to corrosion if the water used as the heat transfer fluid is not treated properly.

- Efficiency loss: Water to air heat exchangers can experience a loss in efficiency if the fins become fouled with dust, dirt, or other debris, which can reduce the surface area available for heat transfer.

Heat Exchanger Plugged

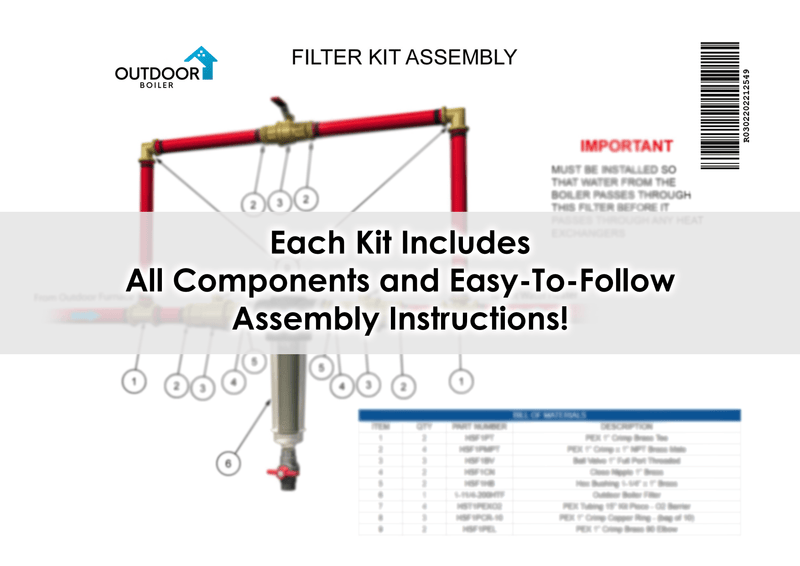

If installing a Filter Kit or replacing the filter cartridge does not improve flow rates, then your heat exchanger will need to be replaced. Again, this can be diagnosed by observing flow through the filter casing after the filter is cleaned. If there is no high flow of water (8-12 GPM), then the heat exchanger may have too much blockage to come back to life.

If you must replace the heat exchanger, remember that if you don’t install a Filter Kit, you will have to replace your heat exchanger again in a few years, so make sure to install a Filter Kit.

Detailed installation instructions are included with every water-to-air heat exchanger purchased at OutdoorBoiler.com.

Conclusion

Water to air heat exchangers are versatile and efficient devices that are commonly used in HVAC systems, industrial processes, and other applications. They offer several advantages, including energy efficiency, cost effectiveness, space savings, and low maintenance.

However, they also have some limitations, including limited temperature range, susceptibility to corrosion, and the potential for efficiency loss due to fouling.

By understanding these factors, you can make an informed decision when choosing a water to air heat exchanger for your application.

All coils come packed in foam to prevent damage during shipping. We are a well established US company with many years of experience selling parts and supplies to the solar and outdoor wood furnace industries. Feel free to contact us with any questions you may have about hydronic heating or cooling parts and supplies whether you bought them from us or not.