Heat Exchangers

Filters

The outdoor boiler heat exchanger is one of the most remarkable discoveries in nature . In the history of the world, no scientist has ever been able to invent a fluid that transfers heat more efficiently than just regular water!

So for example, when a heating fuel is burned, and the heat needs to be distributed throughout one or more buildings, this can be accomplished with a boiler. The advantage of a wood boiler heat exchanger is that the fuel is burned in just one location and the resulting heat can be transferred to a variety of OTHER locations very easily and efficiently. The fuel burned in a boiler heats water. That water is then circulated through hidden pipes to every section of your home and other buildings to provide comfortable warmth without losing any efficiency. Cool right?

(The only small issue is when the boiler is made of steel, it must be protected with a corrosion inhibitor. But we have completely solved that problem with our Liquid Armor Water Treatment.

Click HERE for more information on how to protect your boiler investment.

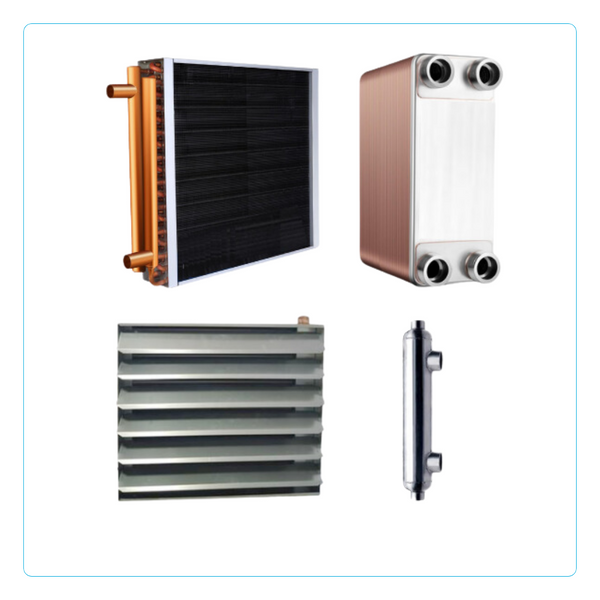

To complete this efficient process, a “Water Heat Exchanger” is required to transfer the warmth from the circulating water into the space to be heated. These heat exchangers come in different forms depending upon their purpose, but the TOP 3 types of heat exchangers are as follows:

Water-to-Air Heat Exchanger

As its name sounds, a water-to-air heat exchanger transfers heat from water to air. Many people think these look like a radiator for a car. The hot water passes through small copper tubes that have metal fins attached. The circulating hot water from the boiler heats the tubes and fins. When warmth is needed, a blower fan turns on and blows air through the fins and tubes and voila – warm air!

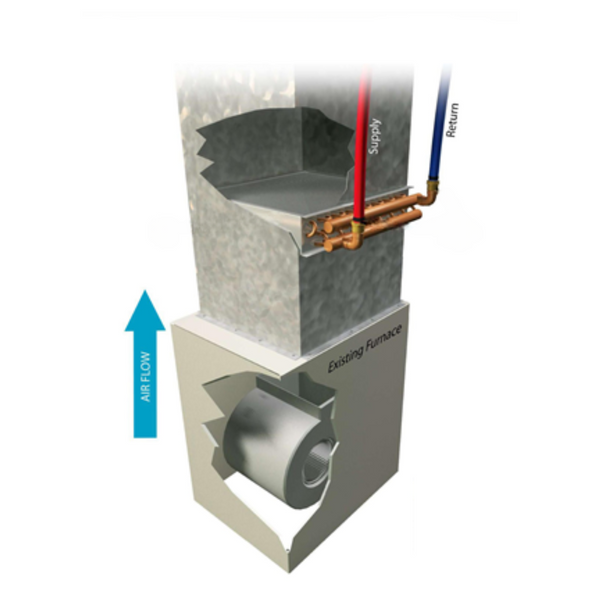

Water-to-air heat exchangers are most commonly used in forced air ducts. See drawing below. These heat exchangers are often installed in the forced air furnace plenum which is located above the furnace. These come in several sizes, and are often installed by simply attaching “L-Brackets” to the inside of the plenum that the heat exchanger lays on in a “flat” orientation.

Detailed installation instructions are included with every water-to-air heat exchanger purchased at OutdoorBoiler.com.

Water-to-air heat exchangers come in different sizes, some as small as 12”x12” for a small room up to 24”x24” and larger for bigger spaces to be heated.

Water-to-Air Heat Exchanger Output and Dimensions

Water-to-Water Plate Heat Exchanger

These heat exchangers transfer heat from one circulating liquid (usually water from the boiler) to a different liquid, WITHOUT mixing the liquids!

These water-to-water plate heat exchangers accomplish this by allowing the hot water (from your boiler) to pass over alternating plates, thus warming them up. The water to be heated is passed through the empty space between those alternating hot plates, which transfers the heat from the boiler water to the other liquid.

For example, to heat your domestic hot water with your outhoor boiler, you will install a “Domestic Hot Water Kit”, which includes a plate heat exchanger so that your outhoor boiler water never mixes with your hot water used in cooking or bathing.

Plate heat exchangers are also used to transfer heat from boiler water to in-floor heating systems, to boiler systems that use baseboard radiant heaters, and to industrial hot water systems such as dairies.

Plate Heat Exchanger Capacity Chart

Our brazed plate heat exchangers come in different sizes based on the application, but typically range from 20 plates to 100 plates.

Plate Material: stainless steel heat exchanger AISI 304L

Brazing Material: Copper

Max Pressure: 652 lbs. per sq. in

Test Pressure: 971 lbs. per sq. in

Plate Material: 0.05

Exchange Area Sq. Ft.: 417 per plate

Max Temperature: 437F

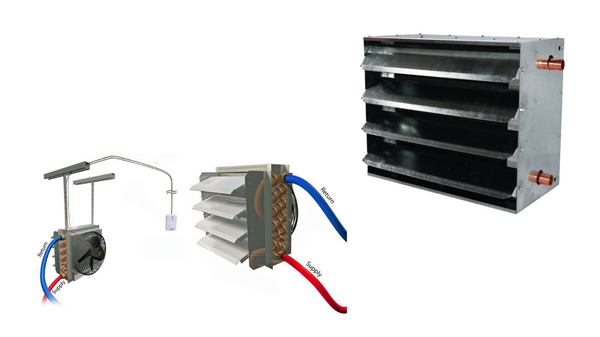

Unit Heaters

The easiest way to heat a workshop or similar spaces is with a “Unit Heater”. This is a self-contained heating system in a small box that includes a water-to-air heat exchanger and a built-in blower fan that turns on and off to keep the room at your desired temperature, according to the setting on your thermostat (thermostat sold separately).

What Size Of Unit Heater Is Needed For My Building?

For a simple formula on how to select the proper size unit heater, click HERE to read our article “How to Calculate the Proper Size Unit Heater”.

FAQS

×Water to air heat exchangers transfer heat from a fluid (typically water) to the air, or vice versa. A car radiator is a type of water to air heat exchanger, because its purpose is to get the heat out of the car engine. Home heating systems will use these heat exchangers to transfer heat from a boiler to make the air nice and warm.

A heat exchanger that is bad may be failing from two potential problems: The fluid could be leaking, or it could be plugged thus preventing proper flow. "Which Type Of PEX Fittings Are Best?" Check the full article here:https://outdoorboiler.com/blogs/news/which-type-of-pex-fittings-are-best

Yes, a heat exchanger in a boiler can often be repaired, depending on the extent of the damage or wear. The repairability of a boiler and heat exchanger depends on several factors, including the type of damage, the material of the heat exchanger, and the overall condition of the unit.

Using a wood stove water heat exchanger offers several benefits, making it an efficient and eco-friendly heating solution. Some include -

- Renewable and sustainable energy source

- Improved energy efficiency

- Off-grid heating option

- Eco-friendly and lower carbon footprint

- Utilizes excess heat from the wood stove

- Provides hot water for various domestic uses

- Suitable for remote areas without access to the main power grid

- Easy installation and maintenance.

The compatibility of a wood burning stove heat exchanger depends on the design and size of your existing wood-burning stove. We recommend checking the specifications and measurements of the heat exchanger to ensure it fits properly and works efficiently with your specific stove.